NR Drop-In Billet Optimizer Compressor Impellers for Holset, Garrett and Borg Warner Turbos

You can read more on our Partner Site

www.motorsportturbo.com

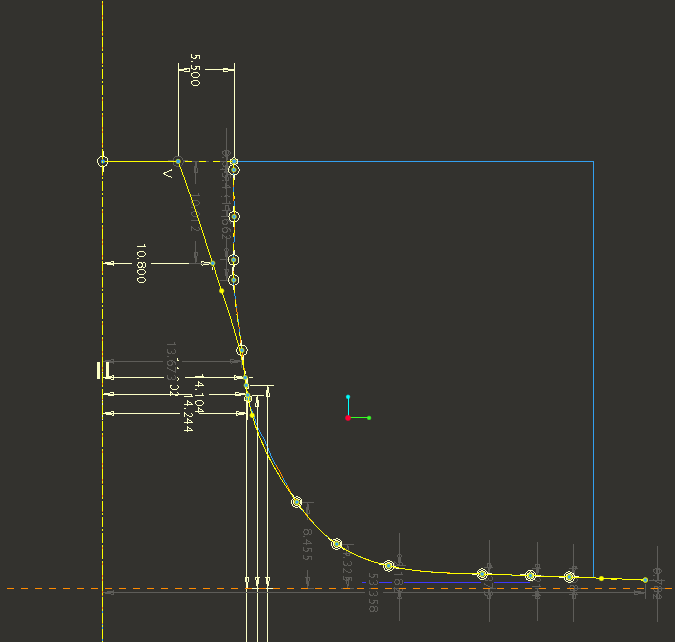

Up to this day, most manufacturers of Compressor Impellers rely on designs from the 1980s and 1920s, that weren't analyzed using CFD code to optimize and size the compressor flow rate and operating pressures to the compressor housing and its involute, causing inefficiencies due to re-circulation, choking and surging.

Our own NR Billet Compressor Impellers are interchangeable with Holset, Borg Warner and Garrett turbos, as drop-in replacement parts. They clearly distinguish themselves from the stock designs, not only in Mass (weight), Spool Up Time, Peak Pressure and CFM, but the billet aluminum round stock used to machine them from is a HIGH STRENGTH AEROSPACE grade "AL".

Custom Cast and Billet Compressor Impellers for Gasoline, Diesel and Performance Applicaitons

Clients looking to increase the power of their engines or to better the efficiency and performance of their turbochargers, by an average of 50 to 300 HP, by only changing the compressor impeller, profit from our CUSTOM DESIGNED and MANUFACTURED billet compressor impellers.

We offer three stages of custom DROP-IN impeller:

1) a. Reverse Engineering of Stock Impeller

b. Reducing of Hub Geometry Cross-Section (extend 100% identical blades to the new Hub)

Engineering / Design Cost: $ 4,200.00

2) a. Reverse Engineering of Stock Impeller

b. Reducing of Hub Geometry Cross-Section (extend 100% identical blades to the new Hub)

c. Changing of Blade Geometry Not Using CFD (Deploying NR "Know-How" to alter "Leading Edge", Inducer Blade Height, Exducer Blade Height, General Blade Shape, Exit Angle

d. Change Blade Pattern (Deploying NR "Know-How" to alter blade pattern in respect to the Inducer Diameter, etc.)

Engineering / Design Cost: $ 6,500.00

3) a. Reverse Engineering of Stock Impeller; Reverse Engineering of Compressor Cover Housing, Modeling of Negative Volume

b. Reducing of Hub Geometry Cross-Section (extend 100% identical blades to the new Hub)

c. Changing of Blade Geometry Not Using CFD (Deploying NR "Know-How" to alter "Leading Edge", Inducer Blade Height, Exducer Blade Height, General Blade Shape, Exit Angle

d. Change Blade Pattern (Deploying NR "Know-How" to alter blade pattern in respect to the Inducer Diameter, etc.)

e. Virtual CFD Testing and Design Optimization (Duplicate Engine/Turbo Environment in a Virtual Environment: Will require Turbo Shaft Speed, High Resolution (Hz) Frequency Boost Pressure & Temperature Reading and preferably INTAKE CFM --NO STRUCTURAL FEA

TESTING of Optimized Impeller Design)

Engineering / Design Cost: $ 27,800.00

By Adding $ 1,300.00 to any above option, 1-3, we will increase the impeller's inducer diameter to your specifications or application requirement.

We offer the machining and casting of prototypes and series parts in conjunction with any of the aforementioned billet compressor impeller packages.

Tractor Pulling and Diesel Racing Turbochargers

Contact us for a tailored turbocharger upgrade, which encompasses everything in between the compressor cover housing and the turbine housing.

Desiring to increase the compressor inducer diameter or changing to a custom turbine impeller / shaft or upgrading the CHRA to high performance ceramic ball bearings? We got the answer and the parts to your inquiry.